Rare earth elements have been becoming a critical part of everyday life and advanced technological development during the past several decades. The rare earth demands are rising and its supplies are in question due to Chinese government export duties. Hence price issue of rare earth element has been widespread concerned. It is considered that the rare earth recycling is not only solving the rare earth elements supply issues on a certain degree, but also avoid environmental pollution caused by carelessly disposed.

Rare earth elements can be served in many key fields, such as rare earth permanent magnet, polishing powder, catalyzer and hydrogen storage material. According to the relevant data, the rare earth permanent magnet take a large proportion in the rare earth consumption structure of the United States, Japan and China, the rare earth permanent magnet can be treated as the biggest engine to Chinese rare earth requirements, therefore the recycling rare earth permanent magnet attracts more and more attentions all the time, particularly recycling NdFeB magnet.

Classification of NdFeB scraps

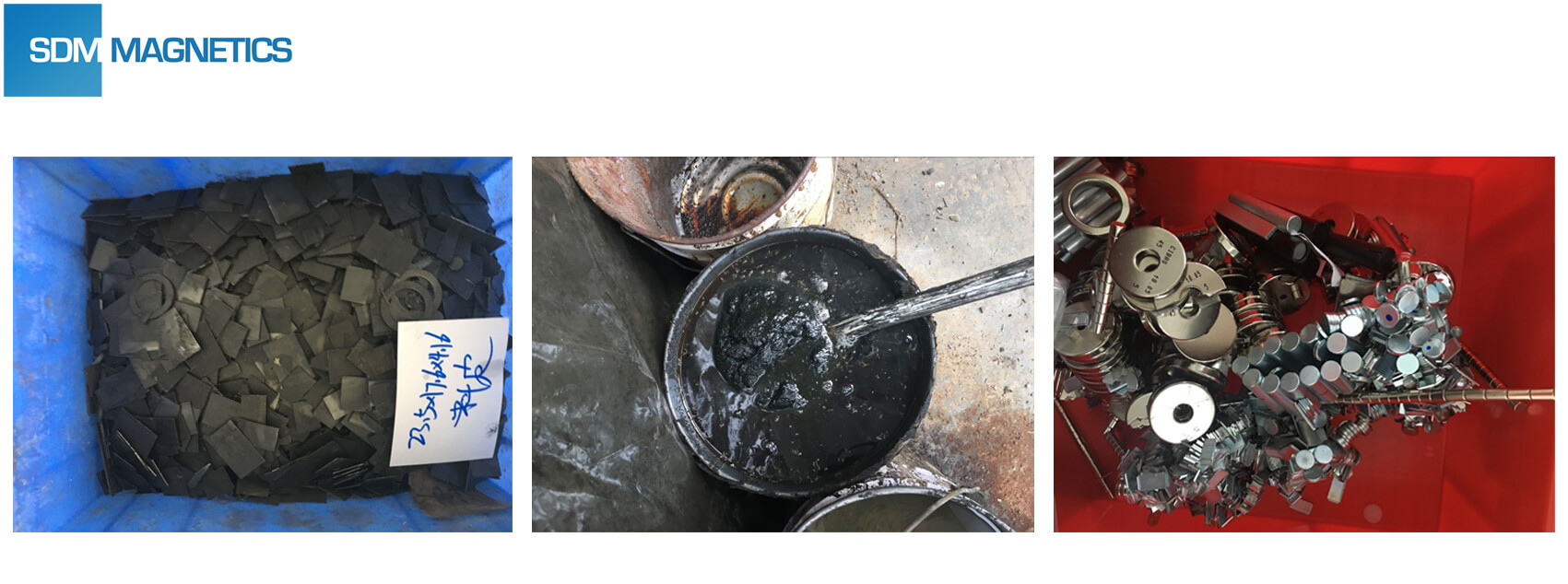

According to Chinese national standard GB/T 23588 “Scraps of Neodymium Iron Boron”, the NdFeB scraps includes:

- Furnace slag material: non-pulverization scraps generated from melting process of NdFeB magnet.

- Powder material: dryand wet powder scraps generated from production of NdFeB magnet.

- Sludge material: sludge scraps generated from machining of NdFeB magnet.

- Block material: block scraps generated from machining of NdFeB magnet.

It should be noted that the main elements of above scraps are neodymium and iron, and the total content of rare earth oxide should not be less than 10%.

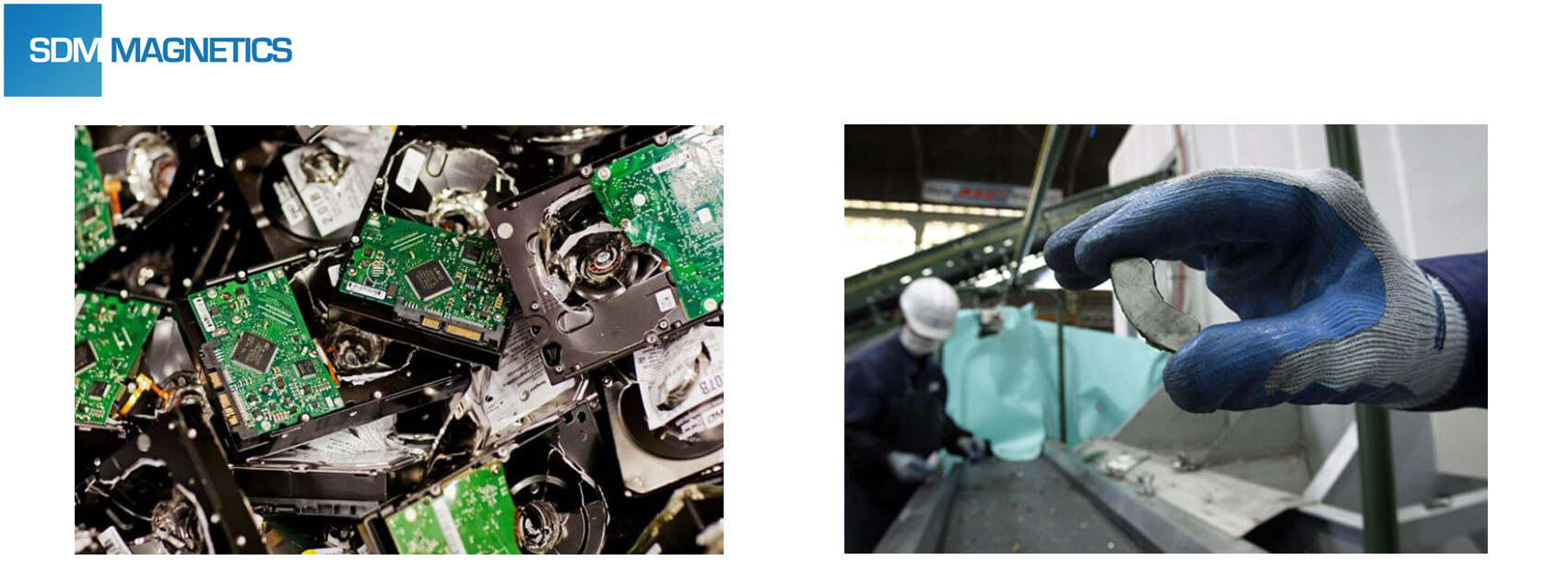

Another national standard GB/T 34490 mentions that the NdFeB scraps should contain end-of-life magnet, and this is also accordant with current research tendency. Upgrade speed of magnet relevant products is very fast, thus a large amount of end-of-life magnet will be created. Actually, these end-of-life magnets are playing an important and complementary role in the NdFeB magnet industry nowadays.

Recycling method of NdFeB sludge scraps

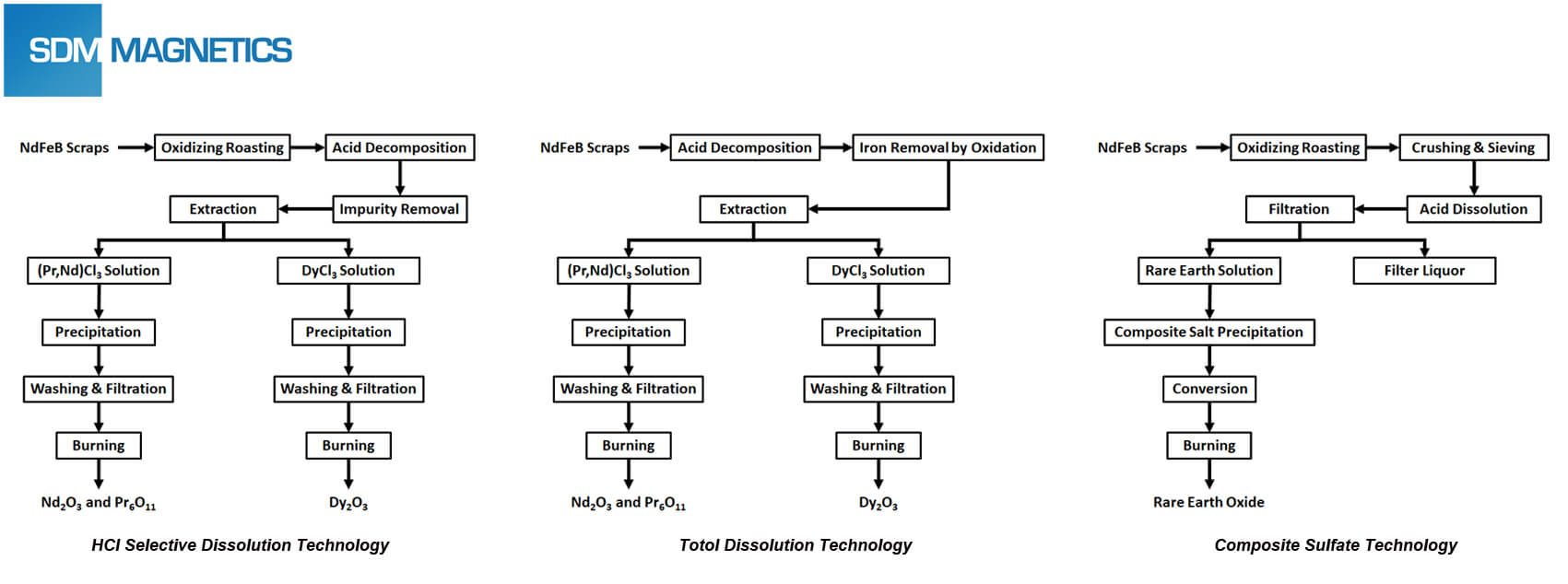

The main stream of NdFeB sludge scraps recycling is the recovery of rare earth element oxide.

The NdFeB powder will mix with cutting fluid in the cutting and a grinding process, and then formed sludge scraps. In fact, NdFeB powder in sludge scraps already seriously oxidized during the machining process. The recycling method of sludge scraps mainly uses hydrometallurgical process.

The total dissolution technology has the simple and reliable process, but its recovery ratio and purity are low.

The selective dissolution technology is the most competitive process for recycling, but the neodymium and praseodymium in the final product cannot complete separation.

The composite sulfate technology is the most widely industrial one in this area. Its by-product will affect human health water resource security and atmospheric environmental yet.

Recycling method of block scraps and end-of-life magnet

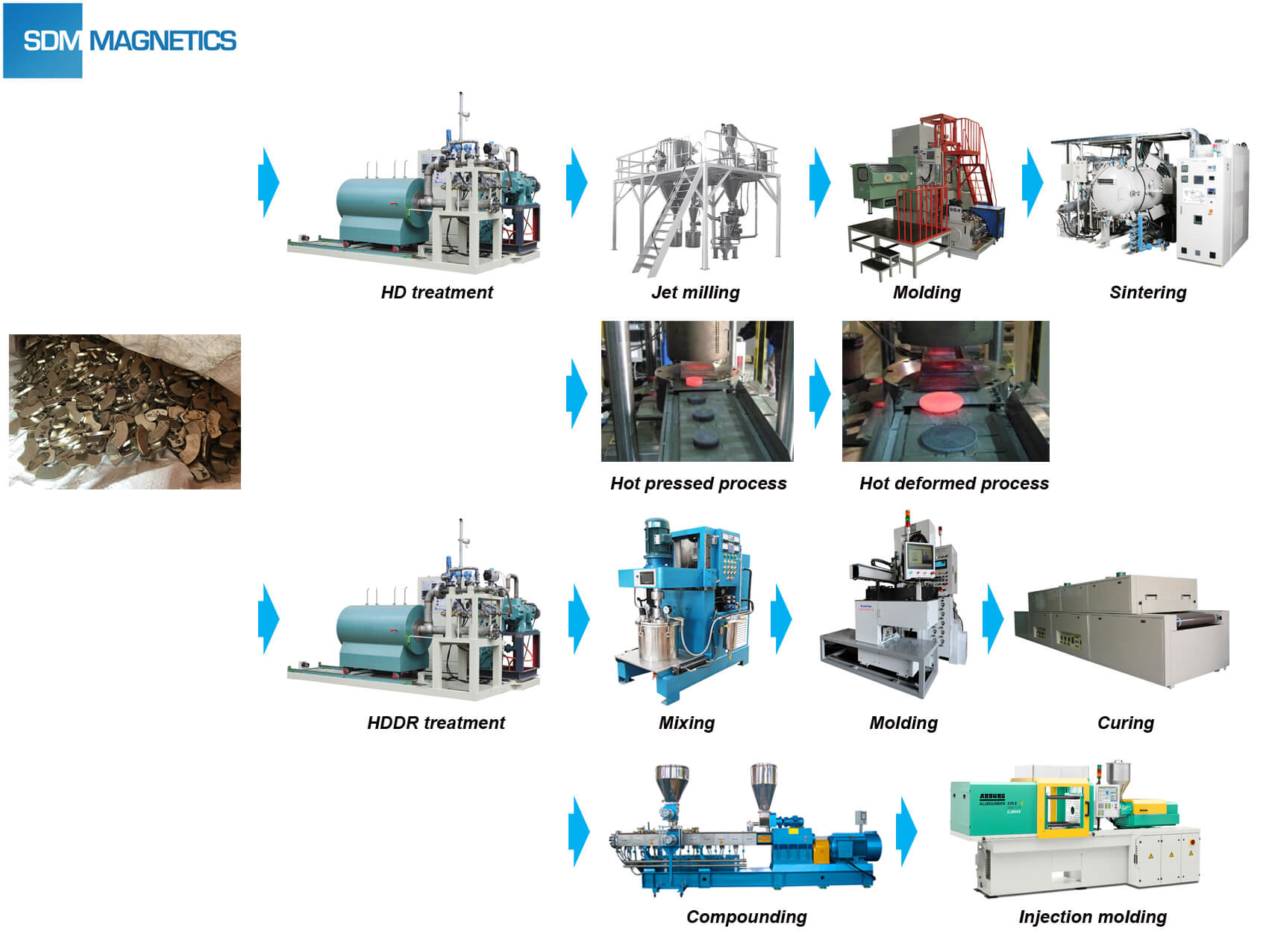

Oxidation degree of block scraps and end-of-life magnet is much lower than sludge scraps, so the large-size block scraps can be machined to small size magnet directly. In truth, hydrogen treatment has long been widely used in China NdFeB industry for many years. Block scraps will crack after absorbed hydrogen under certain temperature and pressure. The hydrogen treatment of block scraps can be divided into HD treatment and HDDR treatment. The HD treatment powder can make sintered NdFeB magnet, and HDDR treatment powder will be applied as the raw material of hot-pressed/hot deformed magnet and anisotropic bonded magnet. For this kind of NdFeB magnet, its magnetic properties will lower than original magnet due to its decreased Nd-rich phase content and increased oxygen content. The proper introduction of Nd-rich phase is very essential for enhancement of magnetic properties. The coating will seriously impact the reaction rate of hydrogen abstraction reaction, the stripping operation before hydrogen treatment is required. Similarly, the reaction rate will be also influenced by the dimension of block scraps.

The end-of-life magnets need a professional and systematically collection, then classify and disassembly before recycling.

September 15, 2021

Recycling method of block scraps and end-of-life magnet

kindly update with the latest process of recycling method of the NdFeB magnet, what type of machine is required for the process and what will be the cost for this project.

September 15, 2021

kindly update with the latest process of recycling method of the NdFeB magnet, what type of machine is required for the process and what will be the cost for this project.